Increasing accuracy in the automotive field simulations

Short description

For complex flow simulations, a priori knowledge of physics and the flow regimes is not always available, so the process of generating an optimal mesh is a tedious, time consuming process associated with a high computational cost. The use of goal driven a posteriori adjoint based error estimation can drive an adaptive process, resulting in a final optimal mesh. The benefits of an optimal mesh are seen in an increased accuracy of numerical simulation results, e.g. for the evaluation of drag or acoustic noise in the automotive and aeronautical fields. By using error estimation and adaptivity, a fully automated process can be established, involving an iterative workflow between mesh generation, simulation, result evaluation and CAD model morphing.

Results & Achievements

The automated simulation methods described above have been extensively used in academia and recently gained interest from both independent software vendors (ISV) and industry. The increasing computational complexity of industrial applications urges the scientific community to provide cutting edge methods packed with solid HPC capabilities to provide reliable solutions in affordable time.

Industrial users are focused on solving engineering problems, and are typically not computing experts. The challenging size of real case problems though, with mesh sizes of several millions of elements, requires that codes are able to run smoothly on Exascale systems.

The coupling Unicorn HPC + FEniCS HPC provides an Exascale-ready framework, with built-in parallelisation of FEM (Finite Elements Method) assembly phase, mesh adaption and linear algebra solvers. Our effort focuses on improving performances and robustness of the HPC solution and filling the gap between academia and industry by testing the code on real case applications.

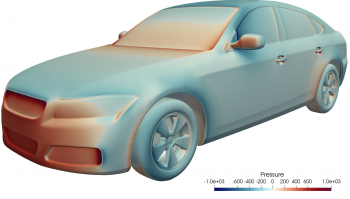

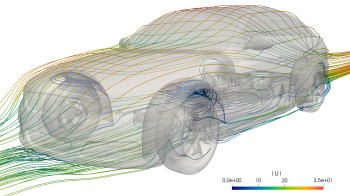

In this context, the joint effort of core code developers and use case owners is addressing the ease of the installation process, as well as the enrichment of the engineering relevant quantities extracted from the solution, the improvement of code stability, the definition of an optimal meshing strategy and the introduction of the drag driven morphing capability. Preliminary solutions have been obtained so far for increasingly complex models of the car.

Objectives

The aim is to use a posteriori error estimation to drive both mesh adaption and CAD morphing in an iterative process to produce an optimal design for a given output of interest. Our strategy is based on Unicorn HPC, a finite element CFD solver built on top of the FEniCS HPC code. It computes an approximation of a weak solution of the incompressible Navier Stokes equation, and comes with a built-in a posteriori adjoint-based error estimation strategy used to drive the adaptive mesh refinement only increasing resolution specifically in regions of interest. Through the adjoint method it is possible to evaluate the sensitivity of a desired scalar output to a change in the solution, without explicitly recomputing the solution. The scalar quantity at hand can be a physical quantity of interest, e.g the drag, or the norm error of the computed solution, related to the mesh size. We are thus applying the adjoint-based techniques implemented in the code for mesh adaptation to enable the drag-reduction based morphing of the geometry model.

Collaborating Institutions

–