Success Story: AiiDA Platform Accelerates Materials Discovery

Highlighted Centre of Excellence

MAX (MAterials design at the eXascale) is a European Centre of Excellence which enables materials modelling, simulations, discovery and design at the frontiers of the current and future High Performance Computing (HPC), High Throughput Computing (HTC) and data analytics technologies. >> Learn more about MAX

Quick Summary

-

Industry Sector Involved:

Materials for energy

-

Software and hardware used:

AiiDA (Automated Interactive Infrastructure and DAtabase for computational science), developed by MaX CoE and partners, including NCCR MARVEL and Bosch Research, on the Piz Daint supercomputer at Swiss National Supercomputing Centre (CSCS).

-

Challenge:

Finding new candidate materials for application as solid-state electrolytes in next generation batteries.

-

Solution:

A simple and efficient framework to predict the diffusion of lithium ions (Li ions) in solid-state materials, then using the AiiDA platform to employ it in a large-scale computational screening.

Organisations Involved:

NCCR MARVEL is a center on Computational Design and Discovery of Novel Materials created by the Swiss National Science Foundation in May 2014. MARVEL targets the accelerated design and discovery of novel materials, via a materials’ informatics platform of database-driven high-throughput quantum simulations, powered by:

NCCR MARVEL is a center on Computational Design and Discovery of Novel Materials created by the Swiss National Science Foundation in May 2014. MARVEL targets the accelerated design and discovery of novel materials, via a materials’ informatics platform of database-driven high-throughput quantum simulations, powered by:

- advanced electronic-structure capabilities, for predictive accuracy

- innovative sampling methods to explore configuration/composition space

- application of big-data concepts to computational materials science.

Bosch Research and Technology Center: Founded in 1999, the North American division of Corporate Research at Bosch has been shaping the technology of Bosch’s future for nearly 20 years. The team has worked in close collaboration with its colleagues and counterparts in Germany and around the world. The center is committed to providing technologies and systems for the four business sectors of Bosch — Mobility Solutions, Energy and Building Technology, Industrial Technology and Consumer Goods – by scouting and collaborating with top universities and industry partners in North America.

CHALLENGE:

Solid-state electrolytes have the potential to enhance both safety and performance of Li-ion batteries, allowing for novel cathode and anode chemistry, preventing the growth of Li–metal dendrites — the needle-like formations of lithium that grow inside batteries, causing devices to lose power more quickly, short out, or sometime even catch fire — and pushing the miniaturization of battery cells.

Despite intense research in this field for decades though, no known solid-state ionic conductor satisfies all the requirements needed for battery applications. This makes the search for new materials a worthwhile endeavor. Computational approaches in the search for new materials are less human-intensive and easily parallelizable and precede synthesis and characterization in the laboratory. Computational screening relies on simulations of the electronic structure, to determine the insulating character of a material, and molecular dynamics simulations to predict the Li-ion diffusion coefficients.

Overall, thousands of calculations need to be performed, making automatization and reproducibility a key requirement. In addition, methods need to be computationally inexpensive enough to be run on thousands of materials, yet accurate enough to be predictive.

SOLUTION:

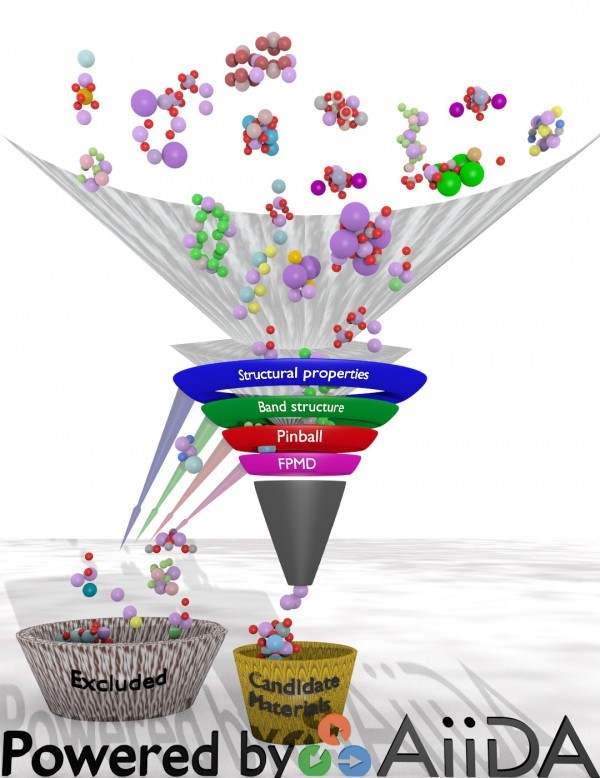

We first reduced the computational burden of modelling the potential energy surface of lithium diffusing in a solid-state ionic conductor to develop a workable framework. We then demonstrated a procedure for running these extensive molecular dynamics simulations in a largescale computational screening. AiiDA made this possible by allowing the automation and explicit storage of the provenance. The novelty of AiiDA in the field of materials informatics is that every calculation is stored as a node in a graph, with input data forming incoming nodes, and output data stored as outcoming nodes, that can again be input to a different calculation.

In addition, AiiDA allows for a high degree of automation and parallelization via its daemon. Every calculation presented in the paper “High-throughput computational screening for solid-state Li-ion conductors” was run with AiiDA.

Business impact:

We found five materials with fast ionic diffusion, some in the range of the well-known superionic conductor Li10GeP2S12, such as for example the Li-oxide chloride Li5Cl3O, the doped halides Li2CsI3, LiGaI4, and LiGaBr3, or the Li-tantalate Li7TaO6. In addition, we found 40 materials that show significant diffusion at 1000 K, though they will need to be investigated more thoroughly before their suitability can be determined. All of these potential fast-ionic conductors could be studied further, in more detail, by experiment and simulation, and could result in new fast-ionic conductors or even electrolytes for next generation solid-state Li-ion batteries. Our data could also serve to search for descriptors of fast ionic conduction, which would be of significant interest to the community.

This work benefits society by identifying inorganic solid-state lithium-ionic conductor compounds that could be used as electrolytes to mitigate or overcome the severe safety challenges posed by the use of volatile and flammable liquid or polymer electrolytes in today’s Li-ion batteries. Complete replacement of the liquid electrolyte by a solid ceramic would result in an all-solid-state Li-ion battery, highly beneficial due to the higher electrochemical stability of inorganic electrolytes, compared to their organic counterparts.

Benefits for further research:

- We developed efficient ways of simulating the diffusion of lithium in the solid state and gained physical insight into how charge-density rearrangements or lattice vibrations affect it.

- We developed a framework for predicting the diffusion of Li ions in solid-state materials and a process for applying it in largescale computational screening.

- We identified new ceramic compounds for in-depth experimental investigation

Related Images :